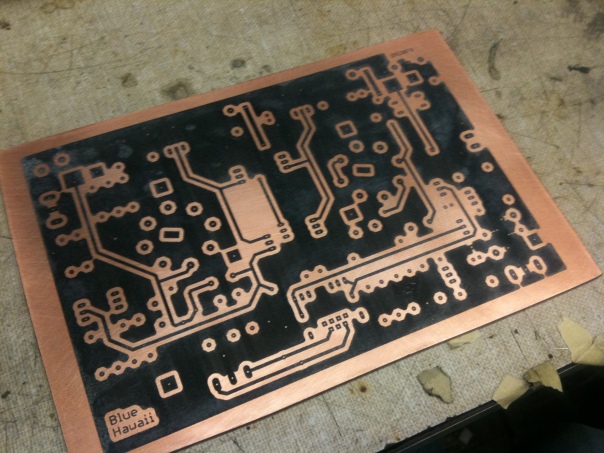

Blue Hawaii

I’ve been working on making a Blue Hawaii electrostatic amplifier (designed by Kevin Gilmore). I’ve spent a lot of work on the chassis which I built myself. I’ve been having some trouble with premature clipping in the amplifier which I still need to sort out, and also need to figure out why there seems to be bandwidth issues above 10khz. Other than that, the project is well on its way to completion.

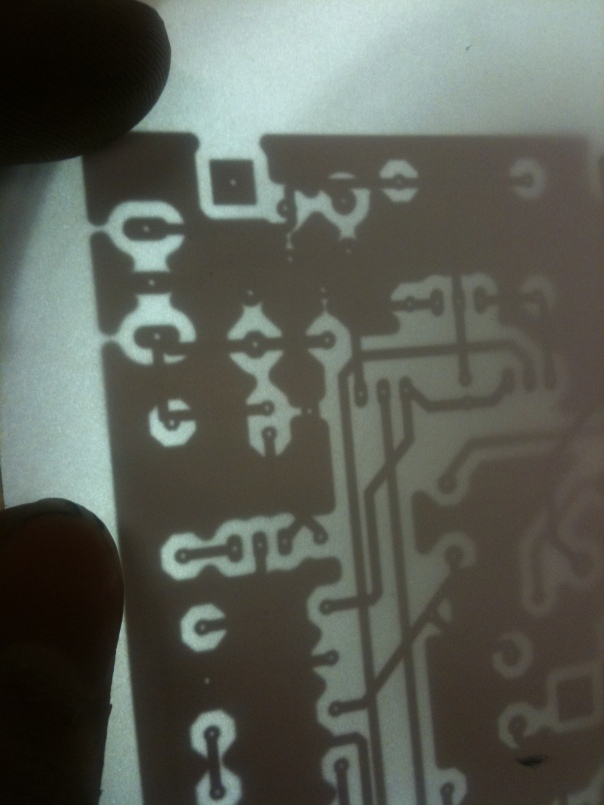

To do toner transfers for double sided boards, I hold the papers up to a light and align them, then tape the papers together to form a sandwich, and slide the board in before transferring. I’ve never had it off by more than a quarter of a drill hole. Usually it’s practically dead on.

Amplifier board after populating

Constant current sources as plate loads

All the boards (bottom right is a slow warm-up for the filaments and a delayed B+)

Milling the heatsink for the back of the power supply to fit a mil-connector and IEC input

Heatsink after cleanup and painting

Since paint isn’t the best of a thermal conductor, I took the heatsink back down to aluminum where transistors will mount. Fastest way was to just mill the surface off.

Covers to go over holes for tubes to exit the chassis

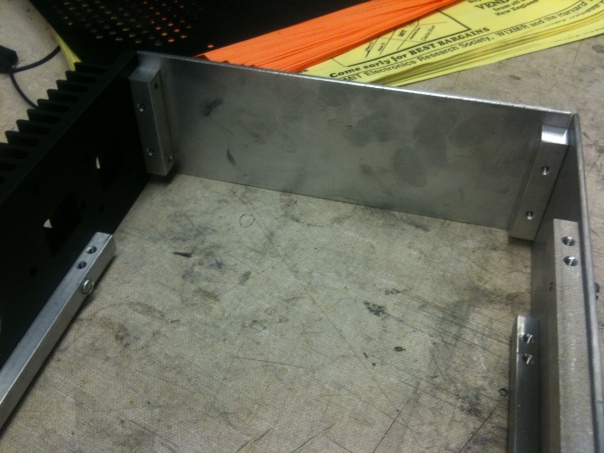

The chassis is built by having bars at each corner that faces screw onto. These were milled to be exactly 90* angles on all sides, so just screw it together and it forms a perfect box.

Drilling mounting holes for the base plate. I laid out the parts in cad (something I rarely do) to get drill positions so I could get all this done before getting boards ready to position.

The nicest box I’ve ever made. All the aluminum panels were polished to near mirror finish with a slight texture

More to come as I put more work into the project.

Posted on June 2, 2012, in Uncategorized. Bookmark the permalink. 3 Comments.

Looks great! You are an inspiration.

This is extremely legit. How did you polish the aluminum? Did you coat it with anything afterwards?

I used a buffing wheel on the drill press with some aluminum polishing compound. Before this, it was sanded to ~400 grit to get rid of large surface imperfections. I didn’t coat it with anything, it’ll be interesting to see what it does over the years. A few months later, it’s still shiny.